Vaults from Buildings: Thin-tile Vaulting from Stabilized Rubble Tiles

year: 2021

Project Phase: Completed

Assignment Type: Research | Design

thin-tile vaulting and its possibility in application in today’s construction, focusing on grassroot buildings and bottom-up construction methods than top-down strategies. We Intend to investigate recycling concrete in the context of post-war for low carbon rebuilding in Syria. Syria has been undergoing a devastating war that left many building in ruins, it is estimate that rubble in the most affected five areas sums to over 45 million tons.

Initiatives of small-scale recycling units is already taking place with locally fabricated presses form cement blocks. While accessible and widespread, introducing recycled thin tiles fabrication within these already establish supply chain can have an impact on their use and application.

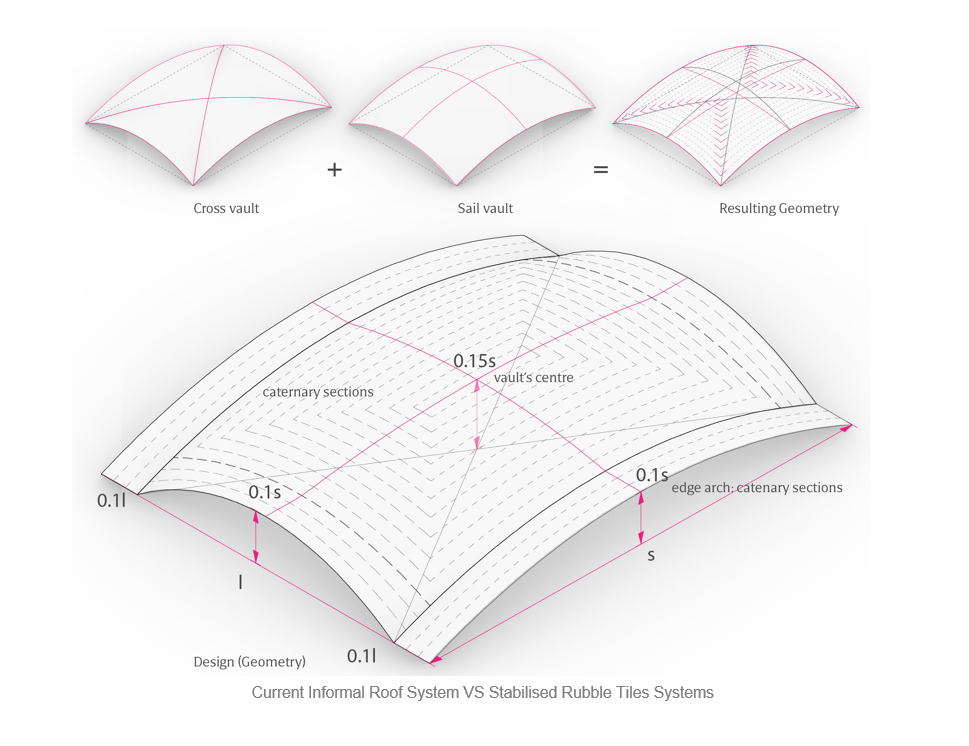

The existing roof-systems in Syria is dominantly concrete based. The Syrian code covers only reinforced concrete floor systems including flat, hollowed, and ribbed slabs. Informal construction in Syria also offers alternative which are, sometimes, faster, and use less materials. We mapped two recurring informal roof-systems. The first is placing CMU blocks directly on I or T section steel beams. The second is covering a grid of small-sectioned steel beams with corrugated metal sheets and casting a 50 mm concrete layer on the top.

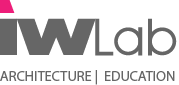

Our proposed vault blends the flatness of a cross vault and the speed of construction of a sail vault geometry. After building edge arches with 1:10 rise, builders can fill-in the vault in a spiral fashion without the need to cut tiles. The proposed design of the thin-tile vault maximises the involvement of low-skilled labour. This limitation incorporated design parameters that results in easy-to-build steps, developed through observing vernacular construction of thin-tile vaulting in Spain and a collaborating with a master vault builder.

The room roof system that was designed in consideration of two things

1- Respond to the Syrian Building Code

2- Be explained and reduced to rules of thumb so that it can have an impact on informal construction too.

We verified this proposal through the making of gravel tiles. After some tests, the final tile mix with acceptable consistency had a cement ratio of 8%. The maximum diameter of the aggregate was 8mm. The tile were manually made, air-dried, and transported to the lab.